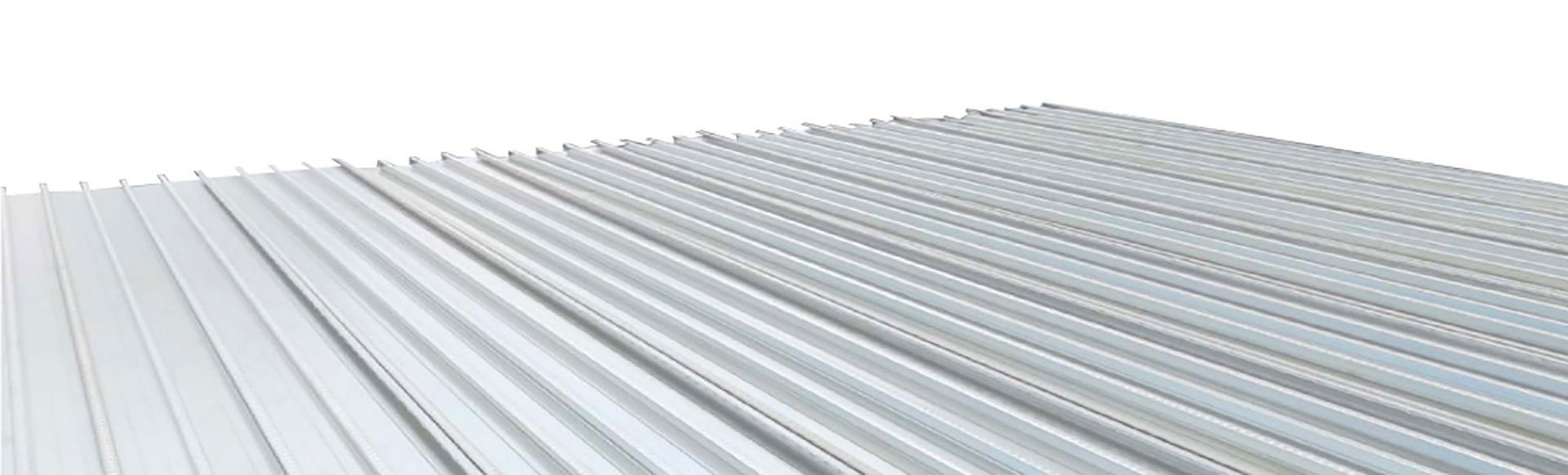

BONDECK 680

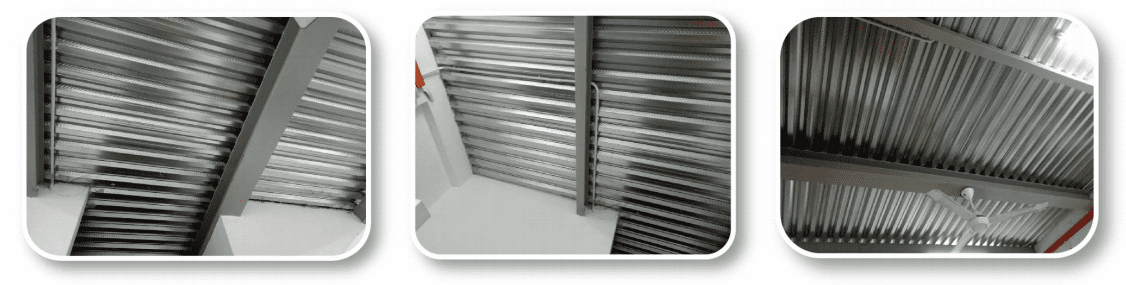

Structural Decking and Ceiling System for Concrete SlabsBONDECK 680

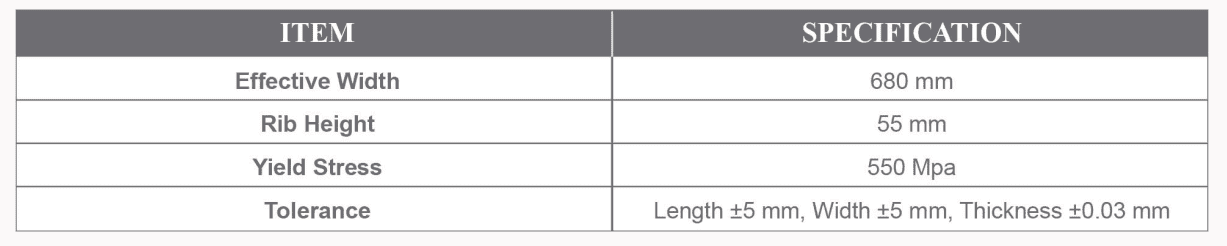

BONDECK 680 Structural steel decking is an efficient, versatile and robust structural decking and ceiling system for concrete slabs. It is a highly regarded formwork product offering efficiency and speed of construction. The steel conforms to AS 1397 and grade G550.

The Features and advantages of using BONDECK 680 are:

- Quick and easy construction

- Safe working platform

- High structural efficiency due to high strength steel used

- Stiffens supporting frame in tall steel buildings

- Excellent spanning capacities for greater strength and less deflection

- Act as a permanent formwork with minimal propping and no stripping of formwork face is required

- Works as composite slab saving on concrete and reinforcement costs

- Advanced design for fire resistance

- Can be used on steelwork, concrete, block work and masonry structures

- Backed by supplier’s warranty

BONDECK 680 is recommended to be used for:

- Concrete frame building

- Residential construction

- Multi-level car parks and multi-storey building

- Commercial building

- Shopping Centre

- Storage Levels

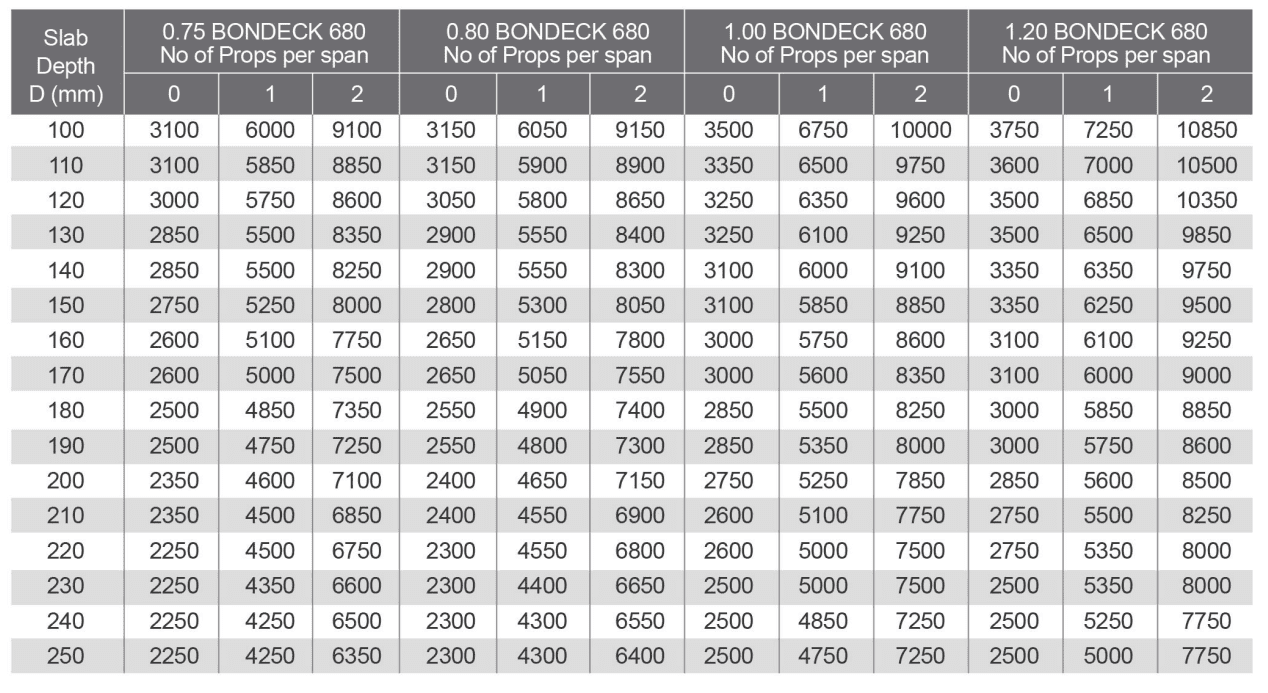

Form/Shuttering/Slab Span Table

BONDECK 680 sheets continuous over two slab

Formwork deflection limit L/240 (or<30mm) visual appearance important

BONDECK 680 sheets continuous over two slab

Formwork deflection limit L/130 (or<30mm) visual appearance not important

Formwork/Shuttering/Slab Span Table

BON DECK 680 sheets continuous over three or more slab span

Formwork deflection limit L/240 (or<30mm) visual appearance important

BON DECK 680 sheets continuous over three or more span slab

Formwork deflection limit L/130 (or<30mm) visual appearance not important

Note: The spanning table above are based on the following assumptions and constraints:

- Density of concrete is assumed at 2400kg/m3.

- The sheets shall be fully supported across the full width and shall have a minimum bearing 50mm at the end of the sheets and 100mm at intermediate support over which sheeting is continuous.

- Construction load of 1.5kPa is assumed.

- Deflection limit of Span/130.

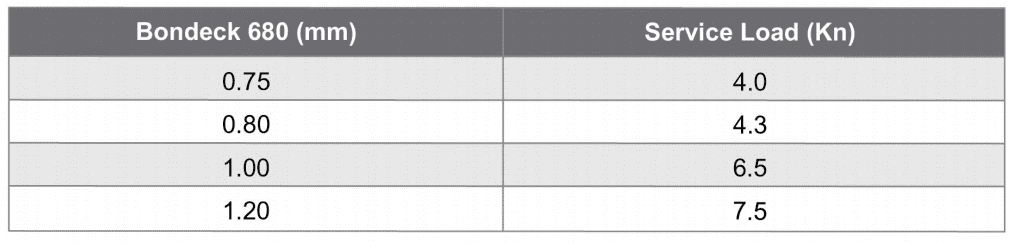

Ceiling Suspension System

The nut is available in three convenient thread sizes (M8, M10 and M12), and may be used to support threaded rods for various services and suspended ceilings.

Safety

Storage and Handling

Propping

Bondeck 680 formwork is normally placed directly on prepared propping. Props must stay in place during the laying of Bondeck 680 formwork, the placement of the concrete , and until the concrete has reached the strength of 20 MPa.

Propping generally consists of substantial timber or steel bearers supported by vertical props. The bearers must be continuous across the full width of Bondeck 680 formwork.

Concrete Placing

When concrete is being poured transversely to the decking ribs, it should be placed first at the edge where a decking sheet is supported by the under lap of an adjacent sheet. This will ensure the longitudinal seams between sheets remain closed.

When a steel deck composite slab is to be poured in conjunction with a band beam, Contractors need to ensure that the temporary ply is positioned.

Interlocking the Sheets

In the first method, lay adjacent sheets loosely in place. Place the female lap rib overlapping the male lap rib of the previous sheet and apply foot pressure, or a light kick, to the female lap rib.

In the second method, offer a new sheet at an angle to one previously laid, and then simply lower it down, through an arc. If sheets don’t interlock neatly (perhaps due to some damage or distortion from site handling or construction practices) use screws to pull the laps together tightly.

Laying

- The slab supports must be prepared for bearing and slip joints as required.

- Lay Bondeck 680 sheets continuously over each slab span without any intermediate splicing or jointing.

- Lay Bondeck 680 sheets end to end. Centralise the joint at the slab supports. Where jointing material is required the sheets may be butted against the jointing material.

- Support Bondeck 680 sheets across their full width at the slab support lines and at the propping support lines.

- For the supports to carry the wet concrete and construction loads, the minimum bearing is 50mm for ends of Bondeck 680 sheets, and 100mm for intermediate supports over which the sheeting is continuous.

- In exposed applications, treat the end and edges of the Bondeck 680 sheets with a suitable edge treatment to prevent entry of moisture.

Fasteners and Locations

When fixing to a steelwork support structure, spot welds, shot fired pins or self-drilling/ tapping fasteners should be used.

Get in Touch

Have questions about our top quality products or professional services? Interested in becoming our valued partner or customer? Simply drop us a line here and we will get back to you as soon as possible.